IS YOUR FAMILY FOREVER SAFE?

DON'T WAIT UNTIL IT'S TOO LATE

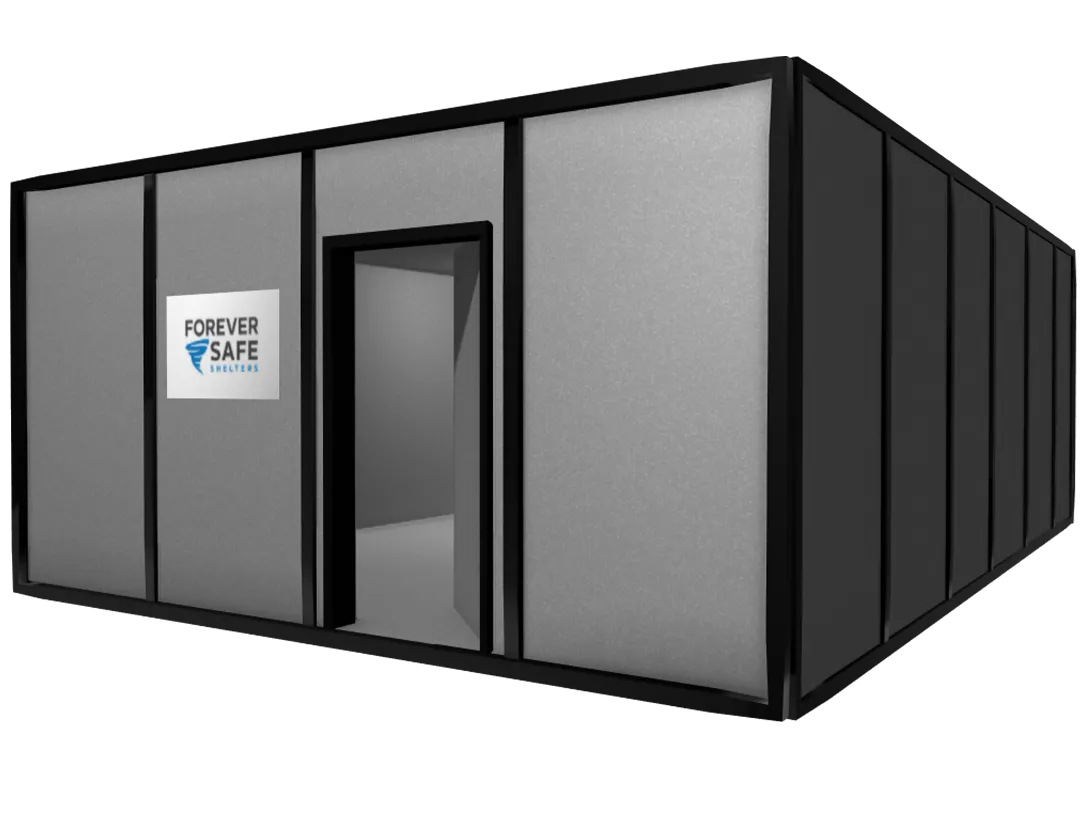

Commercial-Grade Safe Shelters

Forever Safe Shelters provides shelter for your Family, Students and Employees from the threats of gun violence and disasters.

u

u

Tested and Approved

Your security and peace of mind are our top priorities.

Free Estimate

Get a free estimate today and discover affordable, reliable shelter solutions.

About Us

The Perfect Solution for Your Inevitable Problem

At Forever Safe Shelters, your safety is our top priority. With years of experience protecting families and communities, we specialize in durable, life-saving storm and tornado shelters built to stand the test of time. Our expert team is committed to delivering fast, reliable, and affordable protection solutions for homes and businesses. Whether you're preparing for the unexpected or investing in long-term security, you can count on us to keep you and your loved ones safe—because peace of mind starts with a shelter you can trust.

Tested and Approved

Residential and Commercial Safety Shelters

MOST AFFORDABLE

Mini

BUNKER

5-6

4' Wide x 8'8" Long x 8' Tall

Includes Expert Installation

A compact, high-strength shelter built for individuals or 2 people, delivering essential protection in the most efficient footprint available.

STANDARD SIZE

Compact

FORTRESS

10-11

8'8" Wide x 8' Long x 8' Tall

Includes Expert Installation

Perfect for individuals or small families, offering exceptional safety while optimizing space.

BEST DEAL

Guardian

HAVEN

15-16

8'8" Wide x 12' Long x 8' Tall

Includes Expert Installation

A mid-sized shelter designed for medium-sized families or businesses, balancing space and protection.

BEST SELLER

Estate

SAFEHOUSE

28-29

12'8" Wide x 12' Long x 8' Tall

Includes Expert Installation

A large protective structure designed to serve schools, neighborhoods, and estates. Unmatched strength and space to safeguard high-occupancy environments.

LARGEST UNIT

Ultimate

STRONGHOLD

61-62

16'8" Wide x 24' Long x 8' Tall

Includes Expert Installation

A massive, fortified shelter designed for maximum durability and capable of protecting an exceptionally high volume of people in extreme conditions.

CUSTOM

Personalized

CUSTOM

?

? Wide x ? Long x ? Tall

Includes Expert Installation

Shelters have a maximum width of 16'-8" but can extend in increments of 4' in length (16' long, 20' long, etc.) Commercial shelters have thus far expanded as much as 60' long.

Forever Safe Shelters

Multipurpose shelters with a single goal—safety.

Commercial & Residential Grade

SAFE SHELTERS

We know that your utmost concern is the safety of you and your family or employees, as is ours.

HOME

SHELTER

Increase the value, safety, and offering of your home by partnering with Forever Safe Shelters to implement tornado or hurricane shelters into your home.

SCHOOL SAFE

SHELTER

Protect students, educators, and employees from potential gun violence, tornado strikes, or any other natural disaster with Forever Safe Shelters.

GUN SAFE

ROOM

With family and young children in your home, use a Forever Safe Shelter to keep all hunting gear and personal firearm collections organized and secure.

COMMERCIAL

BUILDING

Protect your workplace by securely storing tools, documents, and sensitive equipment while keeping your staff safe during life-threatening emergencies.

Testimonials

What Our Happy Clients Say About Us

Our clients’ trust is our greatest achievement. From quick emergency responses to advanced security solutions, we’ve built a reputation for delivering excellence every step of the way.

"

Forever Safe Shelters have a solution that will “Weather all of life’s storms.” Trust me I tested it myself.

Caleb Holt

Customer

u

Need Help?

Don't Hesitate to Contact Us for More Help.

Have questions or need assistance? Our team is here to help with all your safe shelter needs. Whether it's an emergency, a security upgrade, or general advice, we're just a call away. Don't hesitate to reach out and experience our fast, reliable, and friendly service. Your safety and satisfaction are our priorities!

Frequently Asked Questions

Residential

Why should I consider installing a safe shelter in my home?

A safe shelter in your home offers a secure place for you and your family during emergencies such as severe weather events (tornadoes, hurricanes), natural disasters (earthquakes, floods), or other unforeseen dangers. It is designed to provide immediate protection from harm, potentially saving lives and minimizing injuries during critical situations.

How does a safe shelter contribute to my family's safety?

A well-designed safe shelter is constructed to withstand extreme weather conditions and other emergency scenarios, offering a higher level of safety than other areas in your home. It ensures that your family has a designated place to go where they can be protected from flying debris, collapsing structures, or other hazards. This preparation is especially crucial in regions prone to specific threats, enhancing your overall home safety plan.

What factors should I consider when installing a safe shelter in my home?

Key considerations include the shelter's location, size, and construction standards. It should be easily accessible to all family members, sufficiently spacious to accommodate everyone comfortably, and built according to guidelines that address the types of emergencies you're most likely to face. Additionally, the shelter should be stocked with essential supplies, such as water, non-perishable food, a first-aid kit, and necessary medications.

Can installing a safe shelter in my home affect my insurance rates?

Yes, having a safe shelter can influence your homeowners' insurance rates positively. Insurance companies often view the addition of a safe shelter as a proactive measure that reduces the risk of injury and property damage. As a result, they may offer discounts or more favorable terms on your insurance policy. It's advisable to discuss this with your insurance provider to understand how a safe shelter might impact your rates.

Are there any financial assistance or incentives for homeowners to install safe shelters?

Various financial assistance programs and incentives may be available to help offset the cost of installing a safe shelter. These can include federal and state grants, particularly in areas prone to severe weather and natural disasters. Some local governments and organizations also offer rebates or financial aid to encourage homeowners to take proactive steps in disaster preparedness. Researching local resources and reaching out to emergency management agencies can provide valuable information on what's available in your area.

Commercial

Why is having a safe shelter important for my commercial property?

A safe shelter provides a secure place for you, your employees, and customers during emergencies such as severe weather events (tornadoes, hurricanes), natural disasters (earthquakes, floods), or security threats (active shooter situations). It ensures everyone on the property has access to immediate protection, which can save lives and reduce injuries.

How can a safe shelter benefit my business operationally?

Beyond the primary benefit of safety, having a safe shelter can minimize operational disruptions during emergencies. It enables a quicker resumption of business activities once the danger has passed, reducing economic losses. Additionally, it demonstrates to your employees and customers that their safety is a priority, which can enhance loyalty and trust in your business.

What considerations should I take into account when installing a safe shelter?

When installing a safe shelter, consider its capacity to ensure it can accommodate all individuals on your property. It should be easily accessible and equipped with essential supplies (e.g., water, first-aid kits, non-perishable food). Compliance with local building codes and standards for safe shelters is crucial, as is ensuring the shelter is designed to withstand the specific types of emergencies your area is prone to.

Will having a safe shelter affect my insurance premiums?

Installing a safe shelter can positively impact your insurance premiums. Many insurance companies recognize the reduced risk of injury and property damage when businesses take proactive safety measures. As a result, they may offer lower premiums or discounts. However, it's essential to consult with your insurance provider for specific details, as policies vary.

Are there any financial assistance programs available for installing a safe shelter?

Yes, financial assistance for constructing safe shelters may be available through various programs. This can include federal or state grants, especially in regions prone to severe weather or natural disasters. Some local governments also offer incentives or rebates for businesses that implement disaster preparedness measures. Researching and reaching out to local emergency management agencies can provide information on available funding options.